Description

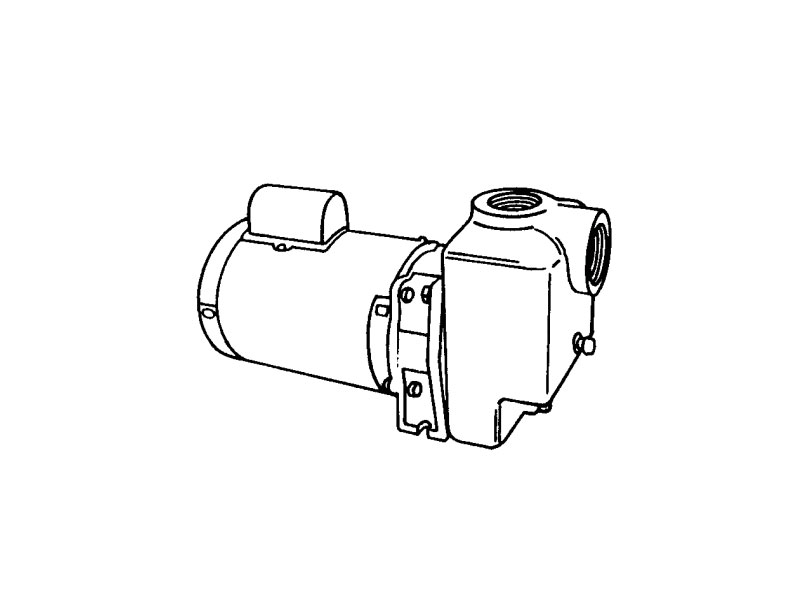

T20WT5-AI Burks Pump

T20WT5-AI Self Priming Pump – Centrifugal

All WT5 General Info

- Compact Close-Coupled Design.

- Rugged Bronze-Fitted Cast Iron Construction.

- Leak Proof Mechanical Shaft Seal.

- Non-Clogging, Bronze Semi-Open Impeller.

- Stainless Steel Shaft.

- Back Pullout Design For Easy Servicing.

- Available With or Without Built-In Basket Type Strainer.

- Self-Priming, Once Case is Filled With Fluid.

- Diaphragms, Flappers or Check Valves Are Not Required In Pump Suction Piping. But Are Recommended.

- EVERY pump is factory tested and thus will meet Hydraulic Institute standards.

Motor Information

WT3A Series also have NEMA Jet Pump Motors. WT5 & WT5X Series consequently have rugged Swimming Pool type motors with oversize ball/ball bearing construction. All motors have open-drip proof construction and are also rated with standard NEMA Jet Pump service factors for continuous duty operation at all ratings shown. Voltages may differ from some suppliers therefore Consult factory. Overload Protection: All single phase motors have built in overload protection. All three phase motors must be installed with a magnetic starter which provides another full 3-leg protection. Failure to use correct starter and overloads will void motor warranty. All Single Phase Open Drip Proof Motors Are especially relevant due to U.L. Recognized.

Ratings

- A3WT3A-1/3 HP, Single Phase, 115V, 60Hz, 3500 RPM, ODP, Split Phase.

- 3WT3A-1/3 HP, Single Phase, 115/230V, 60Hz, 3500 RPM, ODP, Capacitor Start.

- 33WT3A-1/3 HP, Three Phase, 230/460V, 60Hz, 3500 RPM, ODP.

- WT5 and WT5X Series:

- Single Phase: 1/2 HP thru 2 HP, 115/230V, 60HZ, 3500 RPM, ODP, Capacitor Start.

- Three Phase: 1/2 HP thru 2 HP, 230/460V, 60HZ, 3500 RPM, ODP.

Overload Protection

All 56 frame, single phase motors, open drip proof, totally enclosed and explosion proof have built-in overload protection. All three phase motors must be installed with a magnetic starter which thus provides a 3-leg protection for the motor. Furthermore, failure to use the correct starter and heater coils will thus void warranty.

Shaft Seal

The mechanical shaft seal should be replaced if liquid is noticed around the motor shaft. Remove case and impeller. Using two screwdrivers to pry on each side, remove seal stationary seat. Clean seat area of frame, install new stationary seat with ceramic surface facing out and slide new rotating element over shaft with hard carbon surface against ceramic seat. Hence, be sure to keep all surfaces clean. Lubricating seal parts with water will help the installation of the seal. In conclusion, reinstall impeller and pump case.